In late 2009 and 2010 the government made the decision to invest $22 million into the establishment of:

- Four regional export certified, open-access food development and commercialisation facilities, for new food and beverage consumer products and ingredients that can be used by the Food and Beverage industry; and

- The NZ Food Innovation Network company that supports the four regional centres and links key participants in the food innovation system (industry, research organisations and pilot-scale facilities), and encourages collaboration and cooperation between them.

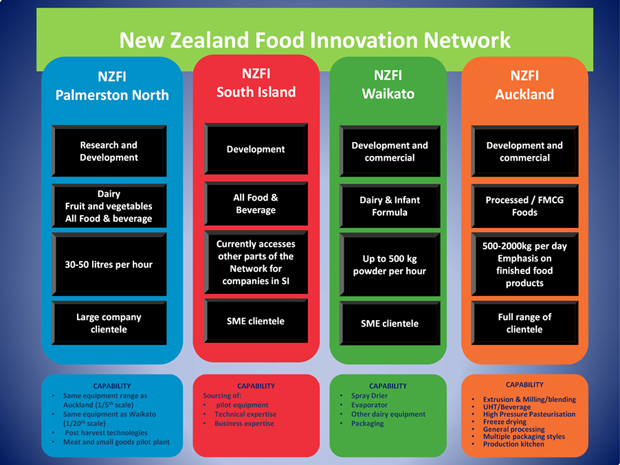

The purpose of these facilities is to support the food industry to improve new product development, innovation and financial performance of NZ’s food and beverage industry. Each centre has a different focus (see diagram above and centre information below). These facilities can support F&B companies in the following ways:

- Develop and test new products

- Make modifications to existing products

- Produce small scale commercial product runs to market test (either at home or in export markets)

- Undertake initial manufacture of new products to help companies to establish the viability of production and purchasing their own production equipment

- Test new packaging and production equipment

- Train staff in the use state of the art equipment (particularly at The FoodBowl, Auckland)

The facilities are located in South Auckland, Hamilton, Palmerston North (at Massey University) and Christchurch. You can contact your nearest centre which will help you access the services that are right for your company.

NZ Food Innovation Auckland Ltd (The FoodBowl)

The Auckland facility is a new purpose-built building housing 6 distinct processing halls that are targeted at finished food products. It is food safe and export accredited (in most areas). Its processing capability includes:

The Auckland facility is a new purpose-built building housing 6 distinct processing halls that are targeted at finished food products. It is food safe and export accredited (in most areas). Its processing capability includes:

High pressure pasteurisation: capable of processing meat, fish, poultry, dairy, fruit; and producing packed meats, ready meals, fruit preparations, meat pastes, hummus and confections.

General purpose area: capable of producing sterilised and baked products including canned products, retort pouches, co-extruded products (energy bars etc).

Liquids/beverage: capable of processing dairy, fruit, vegetable, food flavours, food colour to produce shelf stable products, carbonated beverages, concentrates, extracts packed into PET bottles, glass bottles, bulk packs or cans.

Dry Processing: capable of processing dry products including cereals, dairy, nuts, meat collagen, snacks, baby food, herbs, spices.

Product development kitchen: set up for small scale operation, specifically for SMEs, not intended for export.

Freeze drying: blast freezing or freeze drying capability

Plus a range of other available equipment. For further details please contact Stuart Walker (CE), [email protected]

New Zealand Food Innovation Auckland Ltd I 28 Verissimo Drive, Auckland Airport | Phone +64 9 254 4730 | Fax +64 9 257 0023 |

NZ Food Innovation Waikato Ltd

The Waikato facility is a pre-commercial/ early commercial pilot spray drying facility capable of processing up to 500 tonnes of powder per hour, focusing initially on the dairy industry (both cows and goats). Its future development plans include installing additional equipment to process infant formula and powders for aged care as well as extending the capability to produce plant-based powders.

The Waikato facility is a pre-commercial/ early commercial pilot spray drying facility capable of processing up to 500 tonnes of powder per hour, focusing initially on the dairy industry (both cows and goats). Its future development plans include installing additional equipment to process infant formula and powders for aged care as well as extending the capability to produce plant-based powders.

The facility is expected to be commissioned by the end of May 2012 but is already taking bookings for the new milking season.

Contact: Dave Shute, FoodWaikato, Ruakura Rd, Hamilton, ph: 021 356 912, [email protected]

NZ Food Innovation Palmerston North (The FoodPilot)

Government is funding new equipment for Massey University’s pilot plant which was built in 2007. It will replicate at smaller scale all the equipment found in the other facilities for training and commercial purposes.

Government is funding new equipment for Massey University’s pilot plant which was built in 2007. It will replicate at smaller scale all the equipment found in the other facilities for training and commercial purposes.

All of its facility is food safe and some areas run a risk management plan enabling product developed at the facility to be exported.

Its process capabilities include: dehydration, separation, heat treatment, freezing and chilling, mixing, extrusion and other more general capability and services.

Contact: Allan McBride, FoodPilot, Business Manager, ph: (06) 350 5175 mob: 027 294 9749 [email protected]

NZ Food Innovation South Island Ltd

Because of the small scale of many of the South Island’s food companies, the South Island centre is initially focused on facilitating increased food product development (across the South Island) through accessing existing regionally and nationally available skills and equipment and by providing food product development support services.

This initial activity, which commenced in July 2011, will validate (or otherwise) the demand for and the scope of a pilot facility over the next 12 to 18 months.;

Contact: John Morgan, South Island Director, ph: (03) 325 3749 mob: 027 278 3506 [email protected]

NZ Food Innovation Network Ltd

The Network company has been established to facilitate:

- Inter-hub collaboration and cooperation;

- Future investment in food innovation infrastructure;

- Access to regional food innovation facilities and the wider food innovation system (including research and education);

- Knowledge-sharing across the food innovation system;

- Access to complementary international food innovation networks for manufacturers, researchers and educators; and

- Marketing NZ’s food product development capability (food and equipment manufacturing, innovation, research and development services).

It is owned by the three regional hub companies and Massey University.

Contact: Gaelle Deighton, ph: 021 912 356